kickstand-project.org – The factory of tomorrow is not just a place where machines and robots work tirelessly; it is a dynamic environment where robots and humans collaborate seamlessly to produce goods more efficiently and with greater precision than ever before. This symbiotic relationship between humans and robots, often referred to as collaborative robotics or cobotics, is revolutionizing the manufacturing industry, promising a future where the strengths of robots are complemented by the ingenuity and adaptability of human workers.

The Rise of Collaborative Robotics:

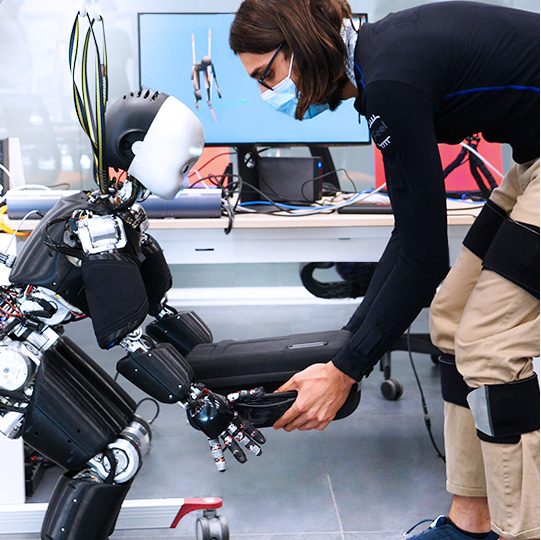

Collaborative robots, or cobots, are designed to work alongside humans in a shared workspace. Unlike traditional industrial robots that operate behind safety cages, cobots are equipped with sensors and software that allow them to detect and respond to the presence of human workers, ensuring safety and collaboration. These robots can be programmed to perform repetitive and physically demanding tasks, freeing up human workers to focus on more complex and creative aspects of production.

Benefits of Human-Robot Collaboration:

The integration of cobots into the manufacturing process offers several benefits. Firstly, it enhances productivity by allowing for continuous operation, as robots do not tire and can work around the clock. Secondly, it improves product quality through the precise and consistent operations that robots are capable of performing. Additionally, cobots can handle dangerous tasks, thus reducing the risk of workplace injuries for human workers. Furthermore, the presence of robots can lead to a more flexible manufacturing process, as they can be quickly reprogrammed to accommodate changes in production requirements.

The Human Element:

While robots bring efficiency and precision to the factory floor, the human element remains indispensable. Human workers bring unique skills to the collaboration, such as problem-solving, decision-making, and the ability to handle unforeseen situations. The factory of tomorrow will leverage these human skills by integrating them with robotic capabilities. For instance, humans can oversee multiple robots, troubleshoot issues, and perform tasks that require a high level of dexterity or sensory perception.

Training and Adaptation:

For the successful collaboration between humans and robots, it is essential that workers are trained to work alongside cobots. This includes understanding how robots operate, how to program them, and how to ensure safety in a shared workspace. As factories adopt more advanced technologies, continuous learning and adaptation will be key for human workers to stay relevant in the industry.

The Future of Work:

The factory of tomorrow will be a testament to the successful integration of advanced robotics and human ingenuity. As robots become more sophisticated and capable of performing a wider range of tasks, the role of humans will evolve. Workers will need to adapt to new technologies and focus on areas where human skills are irreplaceable. This collaboration will not only drive innovation and competitiveness but also create new job opportunities in areas such as robot programming, maintenance, and system integration.

Conclusion:

The factory of tomorrow is a place where robots and humans work together in harmony, each contributing their unique strengths to the manufacturing process. Collaborative robotics is not about replacing human workers but about augmenting their abilities and creating a safer, more efficient, and innovative production environment. As we look to the future, the successful integration of cobots into the workforce will be a key factor in the success of industries worldwide, shaping the way we produce goods and interact with technology. The factory of tomorrow is not just a vision; it is a reality that is being built today, brick by brick, through the collaborative efforts of humans and robots.